Home / CBE

Designed to reduce the volume of aggregates directly on site, CBE crusher buckets for excavator provide optimal performance when working with iron, rock, soil (even humid or wet), wood and deformable materials, thanks to the rotor system.

Ideal for crushing reinforced concrete and demolition waste: the exceptional cutting force generated by high-displacement radial piston motors in direct drive allows any material to be crushed.

Automatic system inverts rotation of the drum in case of blocking (Simex patent).

Advantages

- High cutting force

- Simple, quick tool replacement

- High productivity

- No vibrations

- Easy loading

- UNAFFECTED BY THE PRESENCE OF REBAR

| MODELS AND TECHNICAL DATA | °°° | CBE 10 | CBE 20 | CBE 30 | CBE 40 | CBE 50 |

|---|---|---|---|---|---|---|

| Rec. excavator weight (1) (2) | ton |

8-13 |

10-18 |

16-28 |

24-40 |

38-55 |

| . | lbs |

17500-29000 |

22000-55000 |

35000-61600 |

53000-88000 |

84000-121000 |

| Mouth width | mm |

1030 |

1180 |

1410 |

1630 |

2200 |

| . | inch |

41 |

46 |

55 |

64 |

87 |

| Total width | mm |

1220 |

1485 |

1700 |

1960 |

2440 |

| . | inch |

48 |

58 |

67 |

77 |

96 |

| Bucket capacity (SAE) | m³ |

0,40 |

0,60 |

0,80 |

1,00 |

1,80 |

| . | yd³ |

0,52 |

0,78 |

1,04 |

1,30 |

2,35 |

| Max. cutting force | kN |

80 |

95 |

125 |

152 |

190 |

| . | lbf |

18000 |

21500 |

28000 |

34000 |

42700 |

| Number of teeth | n° |

5 |

5 |

6 |

7 |

10 |

| Bucket weight empty (3) | kg |

880 |

1320 |

2170 |

2900 |

4640 |

| . | lbs |

1950 |

2900 |

4800 |

6400 |

10200 |

| Required oil flow | l/m |

80-160 |

100-190 |

150-250 |

200-350 |

300-550 |

| . | gpm |

21-42 |

26-50 |

40-66 |

53-92 |

79-145 |

| Max. required oil pressure | BAR |

350 |

350 |

350 |

350 |

350 |

| . | psi |

5100 |

5100 |

5100 |

5100 |

5100 |

1) The maximum operating load permitted for the excavator, when added to the weight of the standard bucket, must match or exceed the weight of the crusher bucket at full load.(2) User is responsible for ensuring that the equipment meets the excavator’s specifications and weight requirements. (3) Without mounting bracket.

Simex does not accept responsibility or liability for the information provided. Technical modifications may vary without prior notice.

Features

High cutting force

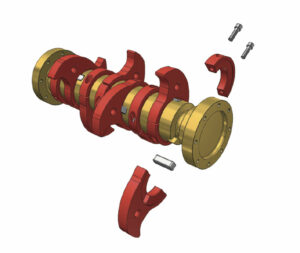

The exceptional cutting force allows any material to be crushed. The rotor with teeth is activated by high-displacement radial piston hydraulic motors in direct drive.

Ideal on concrete and waste material

CBE crusher buckets are ideal for crushing and reducing aggregates and demolition waste directly on site.

Easy tools replacement

The crushing tools easily interlock to the shaft with no weldings and are easily replaceable on site with no downtime due to long technical interventions.

unaffected by the presence of rebar

Crusher buckets can process reinforced concrete, unaffected by the presence of rebar in it.

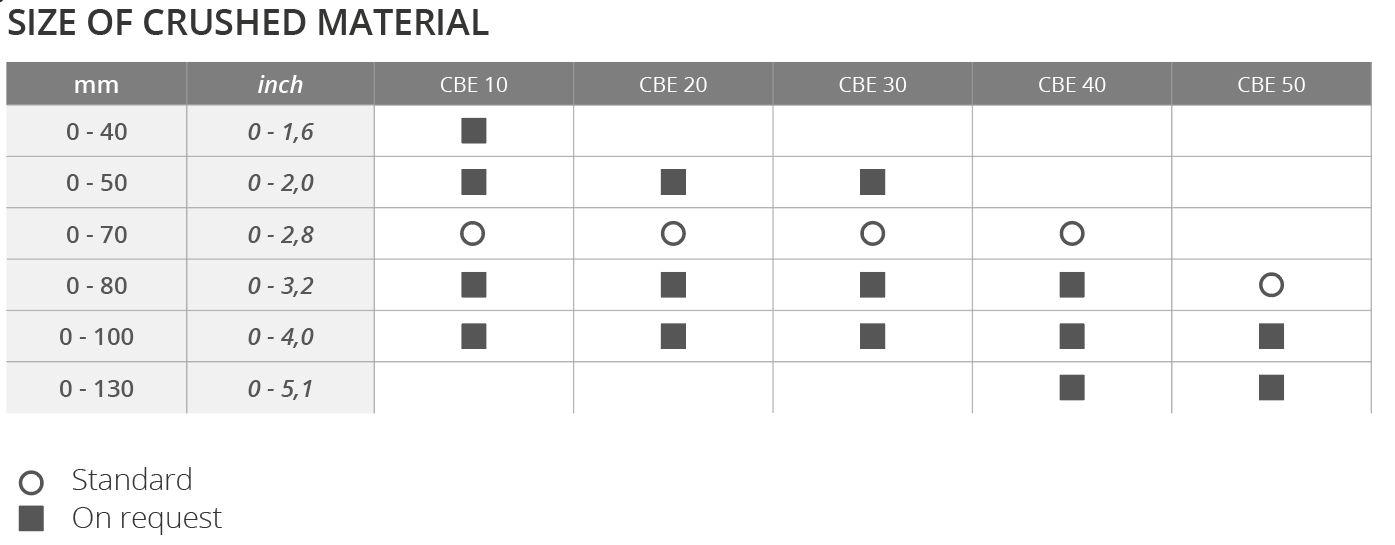

Size of crushed material

Crusher buckets can be equipped, on request, with tools of different measures to vary the output size of the crushed material.

Applications

crushing waste material

In presence of waste material resulting from demolition or construction sites, the CBE crusher bucket finds its perfect application field. Instead of outsourcing the material disposal processes, the operator manages on site the reduction of the aggregates, producing a crushed material that can be reused, for instance, as construction aggregate for building purposes.

crushing rocks

Often, in quarrying applications, the volumetric reduction of rocks (≤100 MPa) must be performed directly on site to facilitate the subsequent material transportation or to reuse it as aggregate for road bases or construction sites. CBE buckets cut the costs for transport and provide an economically valuable crushed material without the need for specific crushing plants.