Home / VS

Designed for separating materials of different sizes directly on site, Simex VS screening bucket - for loader and skid steer - stands out for its easy loading, ease of use and high productivity.

Specific for the selection of waste material deriving from demolitions and excavations, it is also suitable for mixing soils for the subsequent recovery or reclamation.

Advantages

- Easily replaceable screening elements

- Low maintenance costs

- Easy loading

- Safe coupling and decoupling

- Excellent visibility for the operator

- Lightweight frame

| MODELS AND TECHNICAL DATA | °°° | VS 1500 | VS 2000 |

|---|---|---|---|

| Total width | mm |

1550 |

1865 |

| . | inch |

61 |

73 |

| Screening area | m² |

0,5 |

0,6 |

| . | yd² |

0,6 |

0,8 |

| Bucket capacity (SAE) | m³ |

0,45 |

0,55 |

| . | yd³ |

0,59 |

0,71 |

| Output size(*) | mm |

0-20 |

0-20 |

| . | inch |

0-0.8 |

0-0.8 |

| Num. screening shafts | n° |

2 |

2 |

| Bucket weight empty (1) | kg |

790 |

920 |

| . | lbs |

1750 |

2028 |

| Required oil flow | l/m |

70-115 |

70-115 |

| . | gpm |

18-30 |

18-30 |

| Max. required oil pressure | BAR |

250 |

250 |

| . | psi |

3600 |

3600 |

(1) User is responsible for ensuring that the characteristics of the prime mover suit the weight and specifications of the attachment.

* Different output size available on demand.

Simex does not accept responsibility or liability for the information provided. Technical modifications may vary without prior notice.

Features

selection of waste material and topsoil

Designed for separating materials of different sizes directly on site, the VS screening bucket for compact loaders is particularly effective for the selection of waste material deriving from demolitions and excavations, and for mixing soils for the subsequent recovery or reclamation.

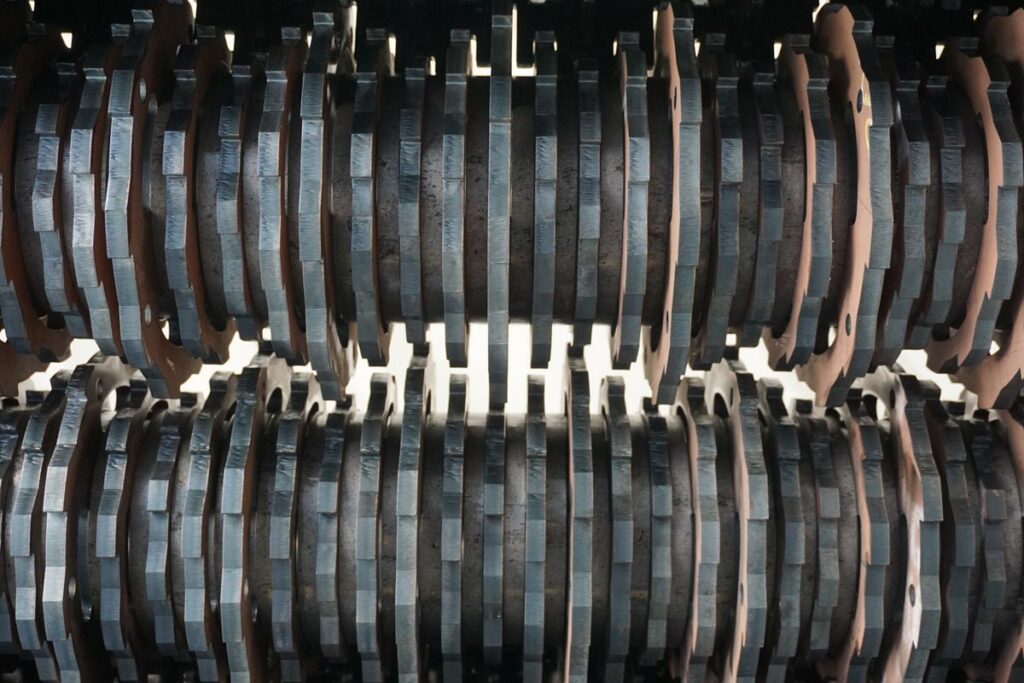

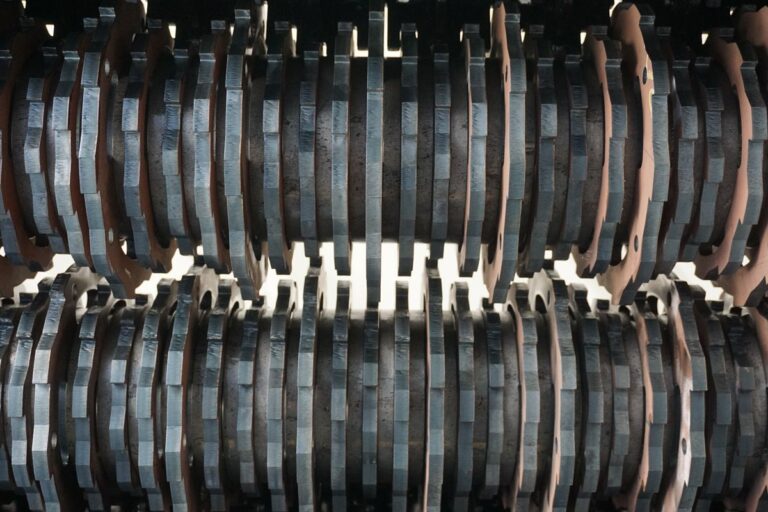

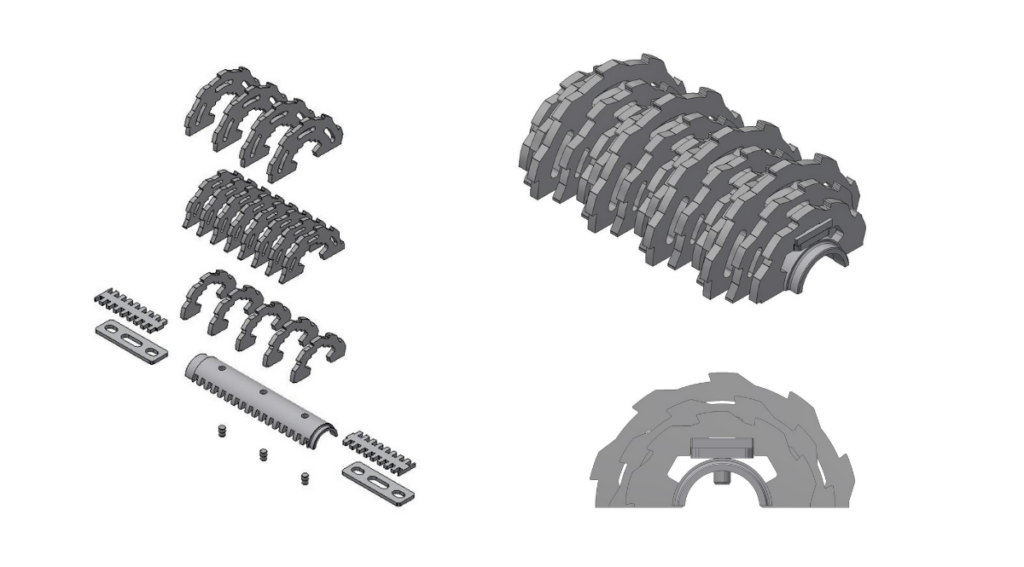

screening tools of different sizes and shapes

Two rotating shafts on which the screening elements, of different sizes and shapes, are mounted, guarantee an intense swirl of the material to be screened.

FIT: the new screening tools

Screening tools are made of discs and blades which interlock the central shaft with no weldings. This means up to 75% less maintenance costs since it is possible to replace even just one single disc or blade, in case of wear. Each element is easily replaceable with a simple procedure that can be performed in minutes directly on-site.

increased profitability

The VS screening bucket was created with the aim of transporting the same quality and construction strength on skid steer loaders as the VSE screeners for excavators, thus allowing operators to optimize processing times and costs even on smaller application and construction sites.

different output size on request

The standard tools configuration produces a recycled material with a size between 0 and 20 mm. Other output sizes are available on demand.

Applications

waste material selection and soil reclamation

VS screening buckets for front loaders are specifically designed for selecting waste material deriving from demolitions and excavations but they work efficiently also for soil reclamation, cleaning it from gravel, stones and debris.